Vertical Machinning Center W1160

Description:

1. The casting is made of resin-bonded sand, after natural aging and twice artificial aging process, it assured good precision and stability.

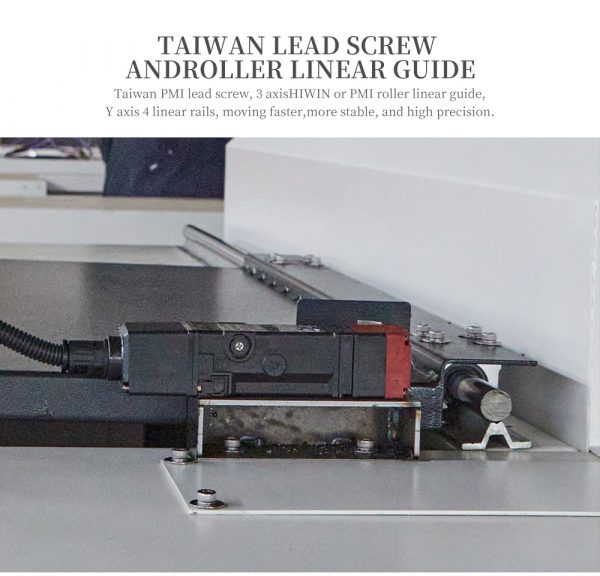

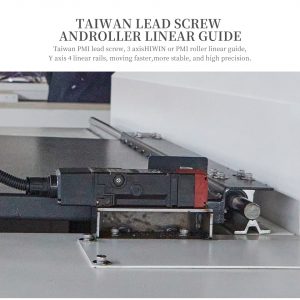

2. Wide base, strengthened column design and precision linear ways for XNYIZ ensure machines’ good performance and precision stability, they are suitable for both rough and finishing machining.

3. High speed silent screw with minimal theral deformation and high accuracy

Application:

This VMC is suitable for mechanical processing and mold making .And it can asapt to the processing requirement from rough machining to finish machining .It can also finish many working procedures like milling ,drilling ,tapping ,boring ,etc.

Product main technical parameters:

| Specification | W1160 | |

| X/Y/Z-Axis Travel | mm | 1100/600/600 |

| Distance From Spindle Nose To Table | mm | 120-720 |

| Distance From Spindle Center To Column Guideway | mm | 650 |

| Spindle Motor Power | kw | 11/15 |

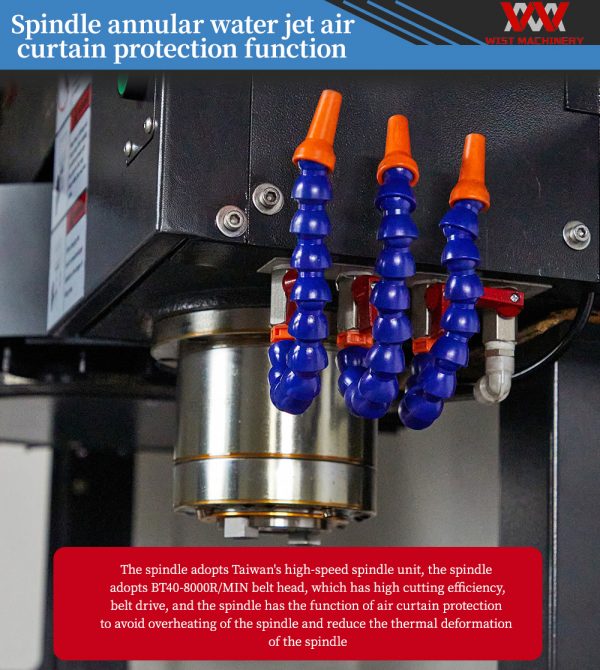

| Spindle Speed | rpm | 8000 |

| Spindle Taper | BT40/BT50 | |

| Positioning Accuracy | mm/300mm | ±0.003 |

| Repeatability Accuracy | mm/300mm | ±0.0015 |

| Working Table Size | mm | 1200×600 |

| Max. Working Table Load Capacity | kg | 900 |

| T-Slot Qty-Width-Distance | mm | 5-18-100 |

| X/Y/Z-Axis Rapid Feed Speed | m/min | 36/36/36 |

| Feed Speed | mm/min | 1-10000 |

| Dia. Of X/Y/Z-Axis Ball Screw | mm | Φ40 |

| X/Y/Z-Axis Servo Motor Power | kw | 3.0/3.0/3.0 |

| Linear Guideway Width And Type/Qty/Block Qty | X-Axis | 45 Roller/2/6 |

| Y-Axis | 45 Roller/2/4 | |

| Z-Axis | 45 Roller/2/6 | |

| Controller | FANUC,Siemens,Mitsubishi, GSK Optional | |

| Max. Power Consumption | kva | 25 |

| Net Weight | ton | 6.5 |

| Overal Dimensions | 3200*2550*2600 | |

Standard accessories:

| Main spindle | belt type | 8000rpm |

| Automatic tool change system ATC | disc tool bank | |

| Oil water separation structure | ||

| Coolant system | standard | nozzle type |

| spindle ring spray | ||

| automatic blowing | nozzle type | |

| oil haze | nozzle type | |

| Chip treatment | front chip | |

| Control system | Mitsubishi M80B | |

| Crystal operation panel | ||

| Handwheel | ||

| Full cover protective sheet metal | ||

| Heat exchanger | ||

| 3-color warning light | ||

| Water gun&air gun for chleaning | ||

| Gas storage tank |

Optional accessories:

| Min spindle | Belt type | 10000rpm |

| Direct connection | 12000rpm | |

| Spinle cooling | oil cooler | |

| Automatic tool change system ATC | Bamboo hat library | |

| Chip treatment | Back chip | |

| Control system | FANUC OI MF | |

| Siemens 828D | ||

| Guangshu , Xindai , Kaiendi | ||

| Electric cabinet air conditioner | ||

| Automatic door | ||

| Oil haze recover device | ||

| Safety door lock |

评价

目前还没有评价