Vertical Machining Center W650

Description:

· Convincing arguments: quality, efficiency and price

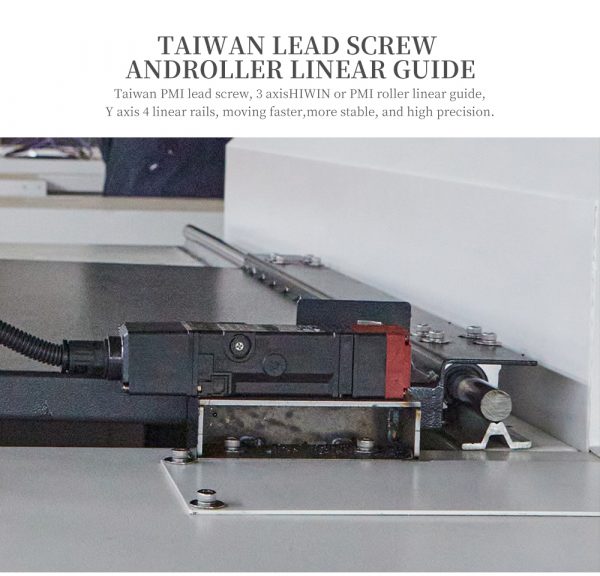

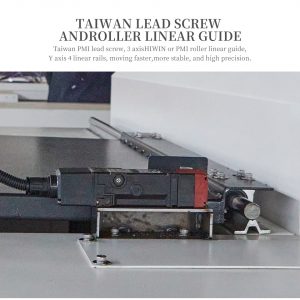

· Imported high rigidity screw, guide rail, coupling and other moving parts, good stability and high precision.

· High-inertia and high-torque feed servo and processing capacity are superior to other manufacturers’ products of the same level.

· Heavy duty roller screw guides on three axis featured with both heavy cutting hard guide and high speed & precision linear guide, low friction and long service life

· Components with CE certification.

· The bus-type system makes the electrical system more stable.

· German technical basic machine body, good rigidity and high precision.

· Equipped with 1ooooRPM high speed servo spindle as standard, no noise and small vibration.

· Nitrogen balance device adopted on Z-axis

· Conform to European Safety Standards(suitable for export)

Specification:

| Specification | W650 | |

| X/Y/Z-Axis Travel | mm | 600/500/500 |

| Distance From Spindle Nose To Table | mm | 100-600 |

| Distance From Spindle Center To Column Guideway | mm | 460 |

| Spindle Motor Power | kw | 7.5/11 |

| Spindle Speed | rpm | 8000 |

| Spindle Taper | BT40(Φ140) | |

| Positioning Accuracy | mm/300mm | ±0.003 |

| Repeatability Accuracy | mm/300mm | ±0.0015 |

| Working Table Size | mm | 800×500 |

| Max. Working Table Load Capacity | kg | 600 |

| T-Slot Qty-Width-Distance | mm | 3-14-100 |

| X/Y/Z-Axis Rapid Feed Speed | m/min | 36/36/36 |

| Feed Speed | mm/min | 1-10000 |

| Dia. Of X/Y/Z-Axis Ball Screw | mm | Φ40 |

| X/Y/Z-Axis Servo Motor Power | kw | 2.0/2.0/3.0 |

| Linear Guideway Width And Type/Qty/Block Qty | X-Axis | 35 Roller/2/4 |

| Y-Axis | 35 Roller/2/4 | |

| Z-Axis | 35 Roller/2/4 | |

| Controller | FANUC,Siemens,Mitsubishi, GSK Optional | |

| Max. Power Consumption | kva | 15 |

| Net Weight | ton | 4.5 |

| Overal Dimensions | 2230*2240*2430 | |

Standard accessories:

| Main spindle | belt type | 8000rpm |

| Automatic tool change system ATC | disc tool bank | |

| Oil water separation structure | ||

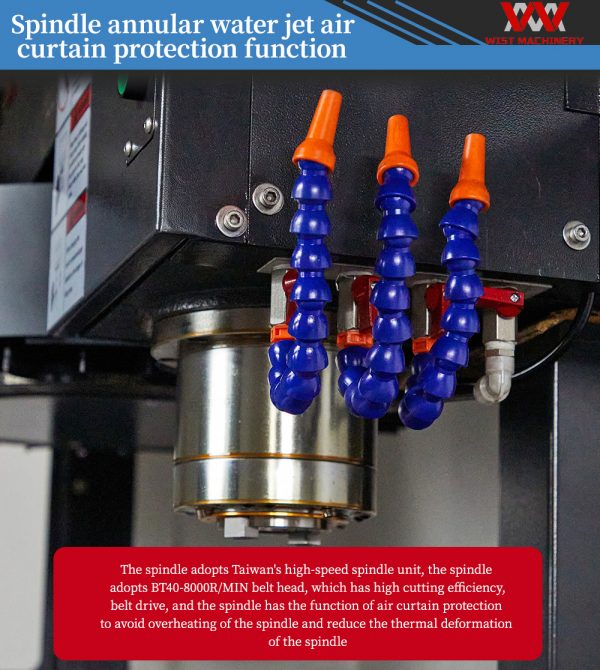

| Coolant system | standard | nozzle type |

| spindle ring spray | ||

| automatic blowing | nozzle type | |

| oil haze | nozzle type | |

| Chip treatment | front chip | |

| Control system | Mitsubishi M80B | |

| Crystal operation panel | ||

| Handwheel | ||

| Full cover protective sheet metal | ||

| Heat exchanger | ||

| 3-color warning light | ||

| Water gun&air gun for chleaning | ||

| Gas storage tank |

Optional accessories:

| Min spindle | Belt type | 10000rpm |

| Direct connection | 12000rpm | |

| Spinle cooling | oil cooler | |

| Automatic tool change system ATC | Bamboo hat library | |

| Chip treatment | Back chip | |

| Control system | FANUC OI MF | |

| Siemens 828D | ||

| Guangshu , Xindai , Kaiendi | ||

| Electric cabinet air conditioner | ||

| Automatic door | ||

| Oil haze recover device | ||

| Safety door lock |

评价

目前还没有评价